Discover

X-SCOPE 90

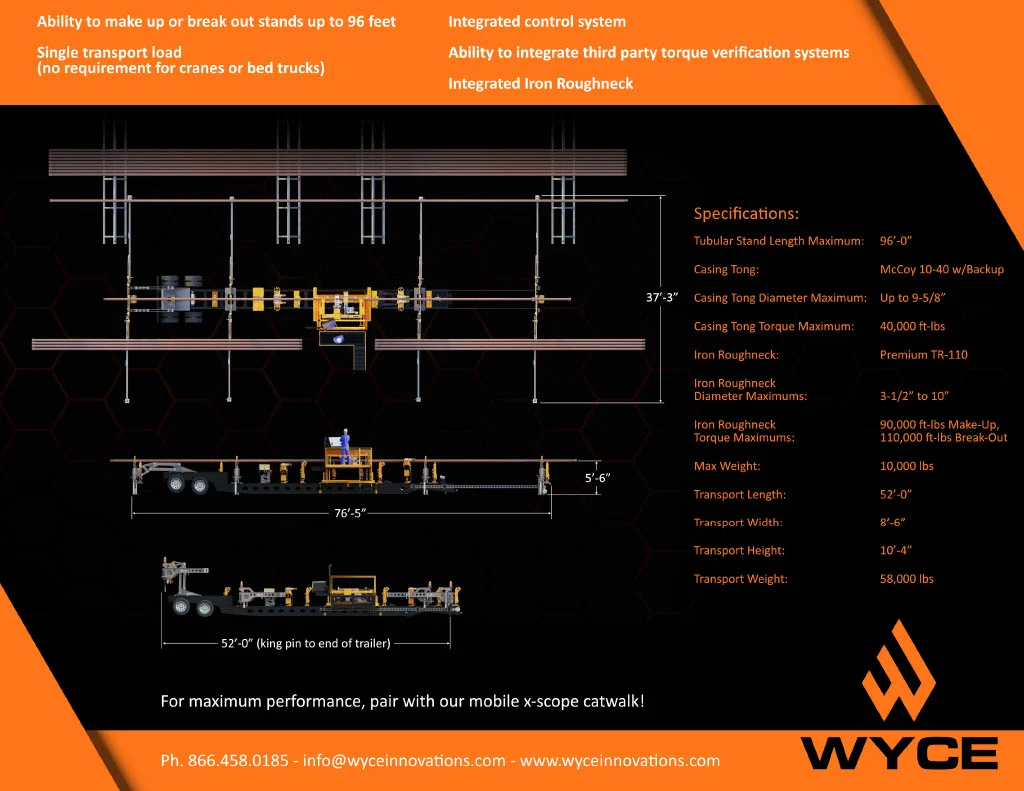

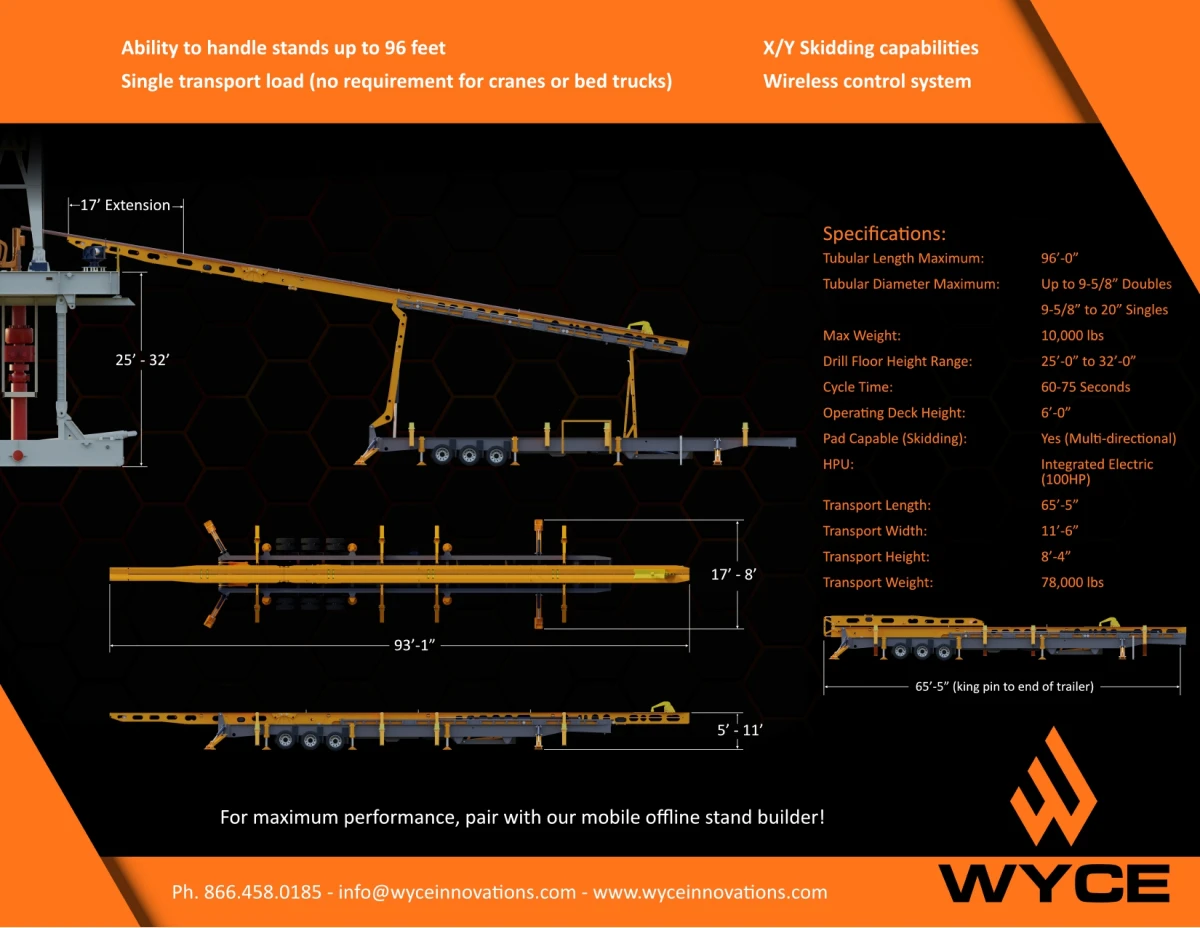

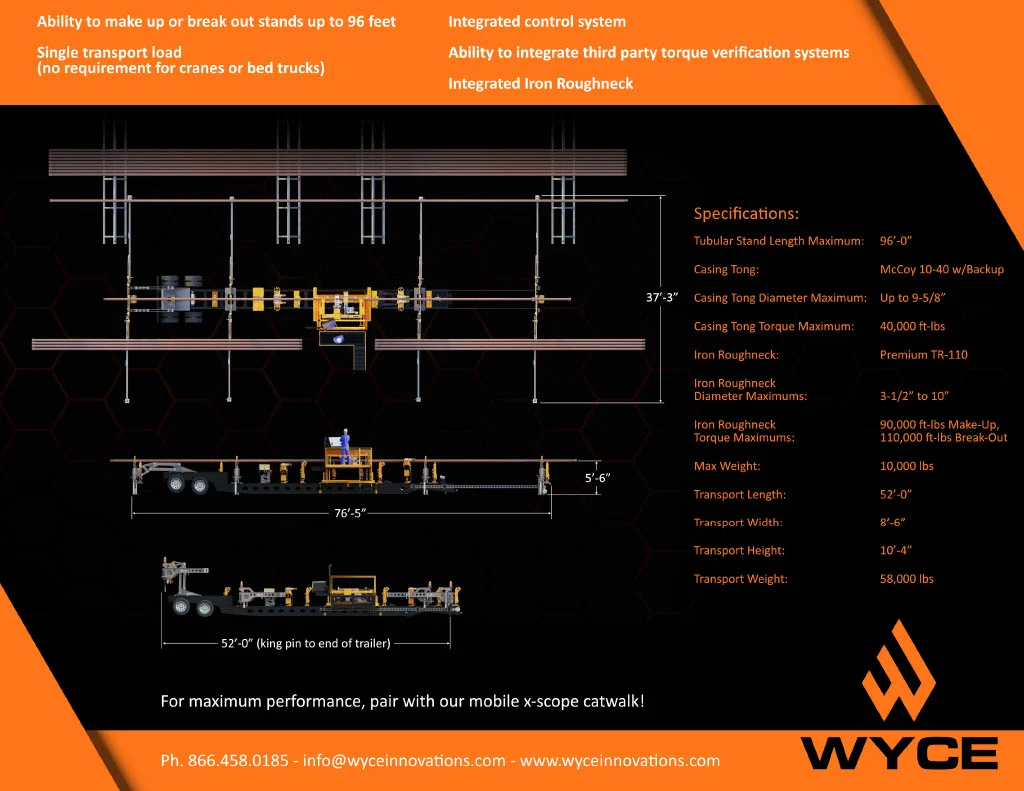

Welcome to the future of drilling operations. The X-SCOPE 90 isn't just a piece of equipment—it's a paradigm shift. By seamlessly integrating automated pipe handling, an advanced catwalk system, and a revolutionary bucking skid, we've created a solution that doesn't just improve your operations—it transforms them.

Discover

X-SCOPE 90

Welcome to the future of drilling operations. The X-SCOPE 90 isn't just a piece of equipment—it's a paradigm shift. By seamlessly integrating automated pipe handling, an advanced catwalk system, and a revolutionary bucking skid, we've created a solution that doesn't just improve your operations—it transforms them.

Detailed Features

Detailed Features

THE X-SCOPE 90 Advantage

THE X-SCOPE 90 Advantage

Real-World Impact 90

In the heart of West Texas, where over 300 rigs are currently operating, the X-SCOPE 90 is already making waves. One major operator reported that after seeing our system in action, they predict 80% of rigs will be running this technology within 4-5 years.

Imagine reducing your casing job times by half. Picture your workers spending less time in harm's way on the rig floor. Envision maintaining your current production levels with fewer rigs. With the X-SCOPE 90, this isn't just possible—it's the new reality.

Real-World Impact 90

In the heart of West Texas, where over 300 rigs are currently operating, the X-SCOPE 90 is already making waves. One major operator reported that after seeing our system in action, they predict 80% of rigs will be running this technology within 4-5 years.

Imagine reducing your casing job times by half. Picture your workers spending less time in harm's way on the rig floor. Envision maintaining your current production levels with fewer rigs. With the X-SCOPE 90, this isn't just possible—it's the new reality.

The Power of Integration

While each component of the X-SCOPE 90 is a marvel in its own right, the true power lies in their seamless integration. This holistic approach to drilling operations is what sets WYCE apart:

The Power of Integration

While each component of the X-SCOPE 90 is a marvel in its own right, the true power lies in their seamless integration. This holistic approach to drilling operations is what sets WYCE apart:

Our Technology A New Frontier in Drilling

At WYCE, we're not just participating in the technological revolution of the oil and gas industry—we're leading it. Our X-SCOPE 90 system represents a quantum leap in drilling technology, seamlessly integrating three core innovations

Our Technology A New Frontier in Drilling

At WYCE, we're not just participating in the technological revolution of the oil and gas industry—we're leading it. Our X-SCOPE 90 system represents a quantum leap in drilling technology, seamlessly integrating three core innovations

Why Choose Us

X-SCOPE 90

Why Choose Us

X-SCOPE 90

Increased Efficiency

The X-SCOPE 90 streamlines operations, reducing time and labor costs.

Increased Efficiency

The X-SCOPE 90 streamlines operations, reducing time and labor costs.

Enhanced Safety

Automated systems minimize human error and increase operational safety.

Enhanced Safety

Automated systems minimize human error and increase operational safety.

Reduced Manpower Requirements

Automation reduces the need for manual labor, allowing for more efficient resource allocation.

Reduced Manpower Requirements

Automation reduces the need for manual labor, allowing for more efficient resource allocation.

Cost Savings

The combined efficiencies and safety features of the X-SCOPE 90 lead to significant cost savings.

Cost Savings

The combined efficiencies and safety features of the X-SCOPE 90 lead to significant cost savings.

Why Choose Us

X-SCOPE 90

Increased Efficiency

The X-SCOPE 90 streamlines operations, reducing time and labor costs.

Enhanced Safety

Automated systems minimize human error and increase operational safety.

Reduced Manpower Requirements

Automation reduces the need for manual labor, allowing for more efficient resource allocation.

Cost Savings

The combined efficiencies and safety features of the X-SCOPE 90 lead to significant cost savings.

The Future is Now

The X-SCOPE 90 isn't just a step forward—it's a leap into the future of drilling. But we're not stopping here. Our dedicated R&D team is constantly pushing the boundaries, ensuring that when you partner with WYCE, you're always ahead of the curve.

The Future is Now

The X-SCOPE 90 isn't just a step forward—it's a leap into the future of drilling. But we're not stopping here. Our dedicated R&D team is constantly pushing the boundaries, ensuring that when you partner with WYCE, you're always ahead of the curve.